As the world embraces Industry 4.0 and embarks on Factory digitization efforts, companies have choices, some more successful than others. The key to these projects is the effective capture and utilization of data. Digitization reduces reaction time, response time and improves transparency, so managers can make decisions about equipment that ultimately contribute to a more efficient operations. When it comes to Enterprise Resource Planning Systems, most ERP vendors capture data at the order and job level. They are not effective at capturing data within a production run.

This is where Sage Clarity Systems is creating a difference with innovative solutions for world-class enterprises that need proactive, actionable insight from their manufacturing operations. An integral part of Sage Clarity’s solutions is Digital Twinning. Digital twin systems for manufacturing are usually built on top of existing IoT systems and used to monitor processes, detect downtime, and predict performance. “Our Digital Twin Replay tools allow you to Pause, rewind, and fast forward through Gigabytes of manufacturing data. This industry 4.0 technology is the next step to achieving the smart factory of the future,” adds John Oskin, CEO, Sage Clarity Systems.

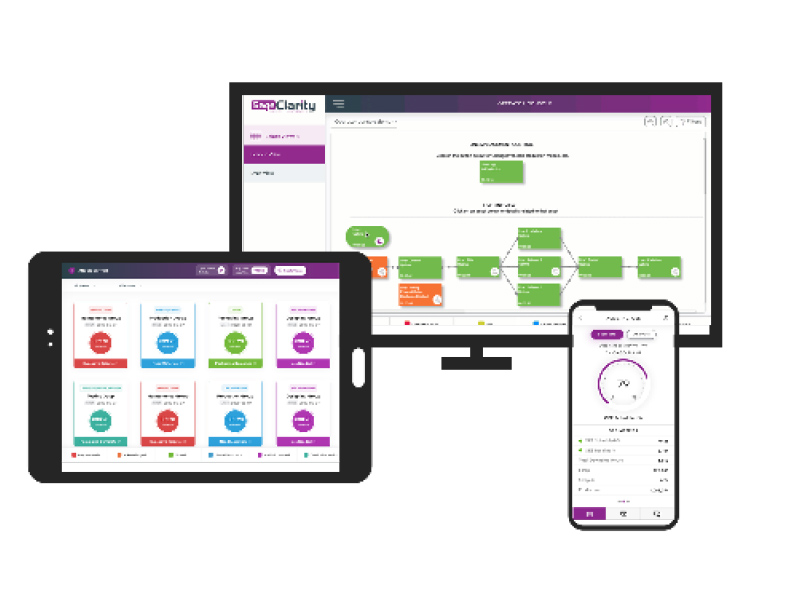

Sage Clarity’s MES Eco system apps allow vendors such as Epicor, a business software company that uses Sage Clarity’s technology to create lightweight IOT solutions that feed relevant data to ERP without overwhelming their systems. The detailed data collection operates at the edge while passing useful information to ERP and providing order context. Moreover, SageClarity’s ABLE Platform, IIoT integrations, and digital twinning solutions enable managers to map every critical junction in the value stream, monitor function in real-time, and diagnose inefficiencies, failures, or line stoppages with precision. This level of dynamic interaction with the value stream opens the door to a better understanding of it and clear, continuous oversight of its operation.

While most digital twin solutions are focused on Product Life Cycle Management, Sage Clarity’s Digital Twin solution focuses on manufacturing operations. With one of the most contemporary IIOT solutions in the market, that can operate at scale, Sage Clarity’s solutions incorporate real-time data collection as its core twinning component.

A classic example of Sage Clarity’s Digital Twin platform in manufacturing is when one of its clients faced a serious crash on an assembly line. Everyone wanted to know what happened and what led up the crash. Using the Digital Twin app, the client was able to replay minute, by minute what led up the crash. In addition, using the ABLE Intelligent Root Cause app, engineers could see how downtime propagated down the line that led to the crash. “Finally, using our next-gen Andon app, notifications are sent to appropriate personnel and both issue response time and resolution is tracked. This creates a digital fingerprint of the issue, the actions taken to resolve the issue and the follow up activity to prevent the issue in the future,” adds Oskin.

Sage Clarity was founded to support the vision of the Next Generation Manufacturing Enterprise. With Industry 4.0 at the cornerstone, the company was started to develop and deliver solutions to drive rapid improvements in manufacturing operations. Today, Sage Clarity has invested heavily in its platform and the company’s innovation lab continues to develop MES Eco system apps as they identify gaps in the market that can be filled with its solutions. The result is a suite of products that be rapidly deployed independently or collectively to drive value in ERP and MES systems.