The human society functions on a host of different principles, but when push comes to shove, none aid our case more than that pledge to grow on a consistent rate. This pledge, in particular, has brought the world some huge milestones, with technology emerging as quite a major member of the stated group. The reason why we hold technology in such a high regard is, by and large, predicated upon its skill-set, which guided us towards a reality that nobody could have ever imagined otherwise. Nevertheless, if we look beyond the surface for one hot second, it will become abundantly clear how the whole runner was also very much inspired from the way we applied those skills across a real world environment. The latter component, in fact, did a lot to give the creation a spectrum-wide presence, and as a result, initiated a full-blown tech revolution. Of course, the next thing this revolution did was to scale up the human experience through some outright unique avenues, but even after achieving a feat so notable, technology will somehow continue to bring forth the right goods. The same has turned more and more in recent times, and assuming one new discovery ends up with the desired impact, it will only put that trend on a higher pedestal moving forward.

The researching team at Massachusetts Institute of Technology has successfully leveraged 3D printing technology to develop a new type of mass filter, which can help us move past those bulky, expensive, and more vulnerable to damage mass spectrometers. Basically, mass spectrometer is a tool widely trusted for identifying chemical substances during crime scene analysis, toxicology testing, and geological surveying. However, despite their clear utility, they suffer from major design and cost limitations. These limitations, on their part, stem from one of spectrometer’s main component called mass filter, a component that pulls all the strings by using electric or magnetic fields to sort charged particles based on their mass-to-charge ratio. Such a mechanism is what allows the wider device to measure the chemical components in a sample and spot out any foreign substance. In practice, the mass filter, otherwise known as a quadrupole, uses a set of four metallic rods to do the job, making up a process where voltages are applied to the rods to make them produce an electromagnetic field. Now, depending upon the properties of the electromagnetic field, ions with a specific mass-to-charge ratio will swirl around through the middle of the filter, while other particles escape out the sides. Therefore, by simply varying the mix of voltages, one can target ions with different mass-to-charge ratios. The problem, notably enough, reveals itself once you consider that a single stainless-steel quadrupole might weigh several kilograms. Mind you, the idea of miniaturizing a quadrupole has been flouted around in the past, but it comes with the potential to introduce errors during manufacturing processes. Another issue is how smaller filters are likely to collect fewer ions, translating to a less sensitive chemical analysis.

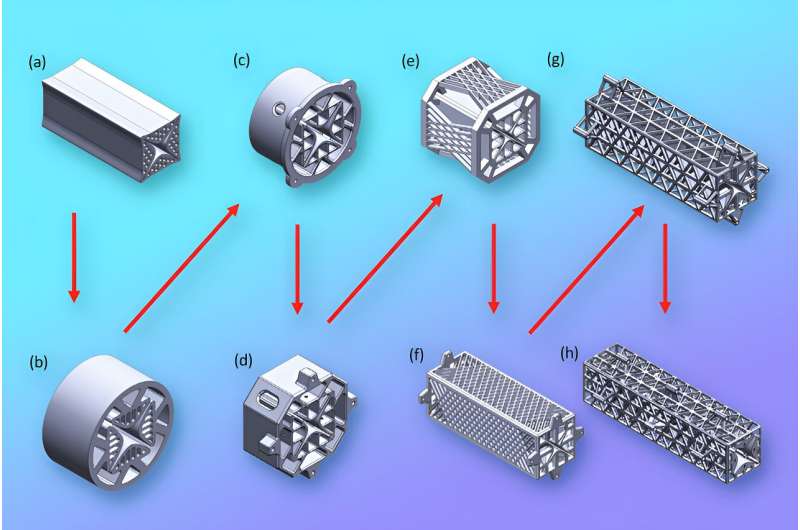

Talk about how did MIT researchers got past the given problem, they leveraged additive manufacturing to make miniaturized quadrupoles with the ideal size and shape to maximize precision and sensitivity. This they did by fabricating the filter from a glass-ceramic resin. In case you weren’t aware, glass-ceramic resin is relatively a new printable material that can withstand temperatures up to 900°C, as well as perform well in a vacuum. To get to their final product, though, the researchers followed one method called vat photopolymerization, which gets a piston to push into a vat of liquid resin until it nearly touches an array of LEDs at the bottom. This cures the resin that remains in the minuscule gap between the piston and the LEDs. Then, a tiny layer of cured polymer is stuck to the piston before it rises up and repeats the cycle, building the device one tiny layer at a time. Interestingly, owing to how the 3D printer can form any shape, the researchers designed a quadrupole with hyperbolic rods. They did so because the said shape is ideal for mass filtering but difficult to make with conventional methods. Apart from it, they also printed an intricate network of triangular lattices surrounding the rods so to conceive durability, while simultaneously ensuring that the rods remain well-positioned, if the device is moved or shaken. Finally, they used a technique called electroless plating to coat the rods with a thin metal film, a move meant to make them electrically conductive. Here, the team covered everything but the rods with a masking chemical and submerged the quadrupole in a chemical bath heated to a precise temperature and stirring conditions. The mechanism would deposit a thin metal film on the rods uniformly without damaging the rest of the device or shorting the rods.

“We are not the first ones to try to do this. But we are the first ones who succeeded at doing this. There are other miniaturized quadrupole filters, but they are not comparable with professional-grade mass filters. There are a lot of possibilities for this hardware if the size and cost could be smaller without adversely affecting the performance,” said Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper detailing the miniaturized quadrupole.

The researching team has already conducted some initial tests on their latest brainchild where they swapped 3D printed quadrupoles into a commercial system and found that the new component could attain higher resolutions than other types of miniature filters. Boasting 12 centimeters of length and one-quarter the density of comparable stainless-steel filters, these quadrupoles were also achieved precision that was on par with large scale commercial filters. The tests even dug into how the new 3D printed quadrupole can be fabricated in a matter of hours, it all can be done in exchange of a few dollars. This marks a major improvement on the commercial-grade mass filters that cost more than $100,000 in investment and also take weeks to manufacture.

“This paper represents a real advance in the manufacture of quadrupole mass filters (QMF). The authors bring together their knowledge of manufacture using advanced materials, QMF drive electronics, and mass spectrometry to produce a novel system with good performance at low cost,” said Steve Taylor, professor of electrical engineering and electronics at the University of Liverpool, who was not involved with this paper. “Since QMFs are at the heart of the ‘analytical engine’ in many other types of mass spectrometry systems, the paper has an important significance across the whole mass spectrometry field, which worldwide represents a multibillion-dollar industry,”

For the future, the researchers’ plan is to scale up quadrupole’s performance even further by making the filters longer. You see, a longer filter can enable more precise measurements, considering more ions that are supposed to be filtered out will escape as the chemical travels along its length. Beyond that, they also hope to explore different ceramic materials that could better transfer heat.

“Our vision is to make a mass spectrometer where all the key components can be 3D printed, contributing to a device with much less weight and cost without sacrificing performance. There is still a lot of work to do, but this is a great start,” said Velásquez-Garcia