In the following post, we will take a look at the meaning of IoT and explore various reasons why companies across different industries need to adopt IoT in their business operations.

Introduction

Regardless of your industry or product, the Internet of Things (IoT), can add value to your business. Thus, companies need to get ready to adopt and incorporate IoT in their businesses.

According to Gartner, “The IoT will continue to deliver new opportunities for digital business innovation for the next decade, many of which will be enabled by new or improved technologies…” In this post, we would take you through 3 reasons why companies need to get ready for IoT but before that, let’s take a closer look at the meaning of IoT.

What is IoT?

IoT(Internet of Things), is simply about connecting things to the internet. “Things” could pretty much be security devices, electronic appliances like refrigerators and what have you. Wikipedia describes the Internet of things (IoT) as a “network of physical objects that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the Internet”.

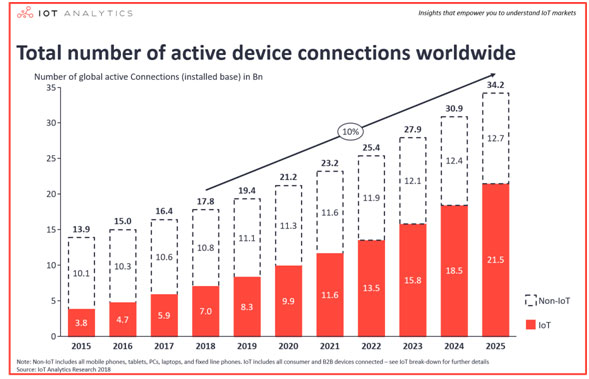

This graph from IoT analytics depicts the steady growth of IoT devices. With more devices connected to the Internet, organizations would need to explore ways to use IoT technology to optimize and innovate on their business as this can give them a competitive edge in their industry.

Some of the reasons why companies should incorporate IoT technology into their business include;

Make informed business decisions with real-time information

Logistics companies can make accurate estimates on the delivery of goods using IoT. With the use of GPS location tags, they can track consignments and get real-time information on where the goods are located in real-time. Apart from tracking, they can also get insights on available goods on the delivery vehicle or on the number of stocks at the warehouse without manually taking inventory.

For manufacturing companies, this real-time information would help in production planning, coordinating customer’s orders and ultimately managing demand effectively. During production, manufacturing companies can also detect supply chain issues in real-time and react faster. With the extensive information available during production, it is easier for manufacturing companies to plan and thus save time, costs and improve the quality of work.

For managers, supervisors or the executive team, business decisions would be a lot smoother with readily available up-to-date information to inform business decisions.

Choosing the right platform to process real-time data is an important decision companies need to make. Traditional data tools might not be able to properly process the data due to the speed at which data is being received and processed. This is where companies turn to Event Stream Processing platforms to process large volumes of data in real-time.

Optimization

With IoT optimizing manual tasks like inventory, workers can concentrate on other areas of the business to boost efficiency. Also, the extensive amount of work that can be done with the help of IoT would lead to a faster output time and improved quality of work. Ultimately, optimizing business processes can lead to a more efficient and profitable business. Logistics companies can optimize their delivery and use location tags to track products and consignments and get real-time information on where the goods are located in real-time.

The type of information gotten from IoT can help companies improve product quality, and also get more insights of product demand to help with forecasting.

Improve Customer Satisfaction

Fast and informed business decisions can lead to customer satisfaction. Providing customers accurate information on the location and time of delivery of their products or showing them the exact information on ongoing manufacturing processes, can foster trust and customer loyalty.

On the other hand, with real-time data obtained from customer behavior, businesses can respond faster to changes in customer behaviour and be the first to provide a solution. In addition, having a detailed knowledge of your customers would help you consistently develop products that would be of value to them.

Conclusion

While some industries like the manufacturing industry are quick to incorporate IoT technology in their operations, other industries like the supply chain industry, are not so fast. “Research shows 70% of retail and manufacturing businesses have already begun to transform their supply chain processes. However, when it comes to supply chain, there is far from a level playing field”.- Forbes.

A main challenge is getting started on integrating the machines and software to process this real-time data. There are a number of IoT technologies to choose from including MQTT, OPC UA among others. Companies would need to determine their use case and capacity in order to choose the best way to get started.

IoT would continue to grow especially with the high demand for data. With this in mind, it makes sense for companies to do a deep dive in their businesses and discover the areas IoT can optimize and automate and also how the availability of real-time data can add to their business.

About the author

Philipp Struss is the co-founder and CEO of Cedalo AG, the company behind Eclipse Streamsheets, a no-code application builder, and Eclipse Mosquitto, the most downloaded MQTT broker.

Philipp Struss is the co-founder and CEO of Cedalo AG, the company behind Eclipse Streamsheets, a no-code application builder, and Eclipse Mosquitto, the most downloaded MQTT broker.