In recent times, the concept of digital twins has garnered widespread attention across various industries and sectors, ranging from manufacturing to healthcare to smart cities. With numerous companies showcasing their capabilities at various industry events, it is clear that digital twins have become a major buzz phrase in the tech industry.

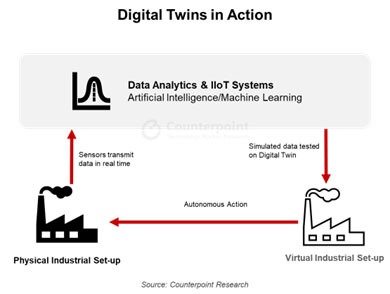

Essentially, a digital twin is a virtual representation of a physical asset and is created using a data structure. IoT (Internet of Things) is used to populate the digital twins data model with data that reflects the current and historical state of the physical asset. In essence, a digital twin provides a real-time simulation of a physical asset, enabling businesses to monitor, analyze and optimize the performance of the asset.

The concept of creating a digital replica of physical objects, systems and processes has opened up new possibilities for improving product design, production efficiency and operational effectiveness. As a result, many technology companies have invested heavily in developing their digital twin capabilities.

Initially used for discrete products in the automotive, and aerospace and defense industries, digital twins have now spread to architecture, engineering and construction (AEC) and engineering, procurement and construction (EPC) projects and play a crucial role in buying, commissioning, and operations management.

Digital twin technologies will be among the fastest growing in the next couple of years with manufacturing and urban planning leading in adoption.

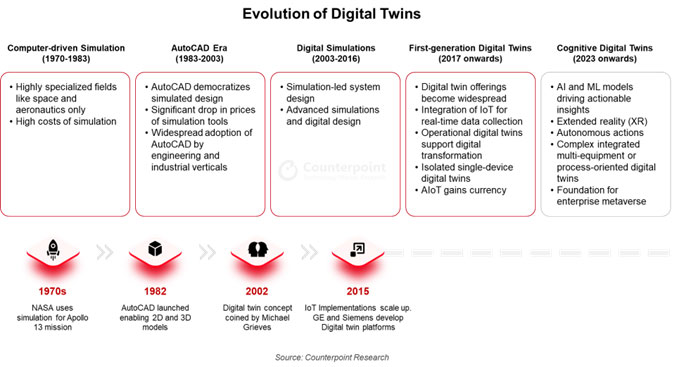

The term “digital twins” was coined in 2002 but it was not until 2017 that IoT implementations picked up pace, giving impetus to digital twins. Currently, we are witnessing the first-generation digital twins, which we can describe as operational digital twins that are collecting data in real time for it to be processed to make decisions. However, most of the digital twins are isolated within the organization which means that the current digital twins are for a machine or a set of machines but not for end-to-end process. The end-to-end process digital twins are complex and need sophisticated AI models, which was not possible a couple of years back.

In 2023, we are entering the era of Cognitive Digital Twins, which are autonomous and use artificial intelligence (AI) for decision-making. Cognition is a computational form that views the mind as a machine, and in the context of digital twins, it is an innovative approach that uses AI to reflect and simulate assets, machines and processes in real time. To develop cognitive digital twins, it is crucial to compute the status, behaviours and relevant interrelated models of real-world elements in digital environments. This computational form is an exciting development in the field of AI and is poised to revolutionize the way we think about and interact with machines and digital systems. We may not see the full-blown cognitive digital twins in the current year, but we do expect the initial implementations to emerge, especially in the automotive and manufacturing environment. Cognitive digital twins would have the following key features:

In 2023, we are entering the era of Cognitive Digital Twins, which are autonomous and use artificial intelligence (AI) for decision-making. Cognition is a computational form that views the mind as a machine, and in the context of digital twins, it is an innovative approach that uses AI to reflect and simulate assets, machines and processes in real time. To develop cognitive digital twins, it is crucial to compute the status, behaviours and relevant interrelated models of real-world elements in digital environments. This computational form is an exciting development in the field of AI and is poised to revolutionize the way we think about and interact with machines and digital systems. We may not see the full-blown cognitive digital twins in the current year, but we do expect the initial implementations to emerge, especially in the automotive and manufacturing environment. Cognitive digital twins would have the following key features:

- Autonomous actions

- Complex aggregation of digital twins

- Use of immersive technologies

Over time, companies would start to connect various digital twins with them, giving rise to enterprise-wide digital twins or, in other words, enterprise metaverse. Not only organizations but even cities and countries are aggregating digital twins to make a larger connected twin. Singapore is the first city to have its digital twin, which is an aggregation of hundreds of digital twins. Digital twins serve as the foundation for the enterprise metaverse, and we envision that enterprises will be powered by multiple interconnected digital twins that involve people, processes and things.

Digital twins have got impetus due to two key developments in the last few years – the rate at which AI is improving and the rate at which the computation cost is declining.

AI is a key component of digital twins. Advancements in AI have enabled digital twins to become smarter and evaluate a large number of possible scenarios to take decisions, making the system autonomous. Generative AI can be a boon for digital twins as it can generate missing or incomplete data. This can be particularly useful in situations where sensor data is missing or unreliable, as generative AI can use available data to generate plausible scenarios and fill in the gaps.

The cost of implementing digital twin technology is rapidly decreasing. This combined with the many benefits of digital twin technology, such as improved efficiency, better decision-making and reduced risk, makes it a compelling alternative for companies looking to optimize their operations and stay competitive in today’s market.