Lean for Export

Most SME businesses in the UK are focused on their local market for their sales for decades. That is one of the reasons they stayed as SMEs. UK market represents very small percentage compared with the potential sales overseas.

The phrase “The world is your oyster” once was said to me by my boss 12 years ago-that stayed with me since then- and I took that with the actual meaning of the world. I was out there travelling most of the world and chasing opportunities for my business. In terms of the results for the business was great but the potential I could see was even greater after being out there and talking to people, existing and prospective customers.

The phrase “The world is your oyster” once was said to me by my boss 12 years ago-that stayed with me since then- and I took that with the actual meaning of the world. I was out there travelling most of the world and chasing opportunities for my business. In terms of the results for the business was great but the potential I could see was even greater after being out there and talking to people, existing and prospective customers.

Let’s say you have identified the export markets you want to be in. You check everything from cultural, legislation, custom practices, market size and everything else that needed for market research and ready to go in. How are you going to win business from the local players in that market (assuming your products and services are not produced only by you)? What will make you desirable for potential customers to switch their supply to you? Can the current products and services you have for the UK be good for them too? The value proposition that you have for your products and services is very important for your prospective customers overseas.

Value

Value is where lean starts from and it is the backbone of everything you would do afterwards. Understanding the value in the eyes of the customer and building that into your product and service means a lot for the customers. The value cannot be defined without mixing with local people and cannot be included into your product and service without understanding it from interacting with them. Customs, legal requirements, legislations, function of the product and service can be searched and found from your desk, but the real value comes out in between lines during conversations with the real prospects and customers at a business setting and from a social setting.

Once you found out about the value, it is important for you to build that into your product and services. That’s where lean implementation bringseverything you need into your business.

Let’s have a look at the most common QCD measures every business is familiar with:

Quality

If you are already successful in the UK market that mostly means that you are offering very good quality on your products and services. You might only be missing out on the repeatability of that quality and your quality is as good as your last delivery of your products and services to your customers overseas. Lean has a long list of tools again for you to produce good quality first time, every time. 5S, standard operations, problem solving, A3 are just some of those tools and techniques. So, when you must prove your quality, lean is your answer.

Cost

Most businesses trying to supply into export markets from the UK face price pressures from the local competition where they are trying to expand their businesses into. Reducing costs means improving productivity for production and services or cheaper inputs into the processes. Lean has long list of tools that you can apply and gain more productivity and effectiveness (not efficiency). Value stream mapping, waste reduction, SMED are just to some of those tools and techniques. So, when you are facing pressures on your costs from export markets, becoming lean is your answer.

Delivery

Your competition overseas will win business over you just because they are quicker to supply or respond to customer needs. Your lead times can be accepted in the UK but when you are looking at expanding into the other markets overseas, most of your prospective customers will look at the lead time effects onto their operations. If they were to accept longer lead time from you, they will have to keep more stock and employ more capital into their businesses. Often, they will ask you for better prices than local competition to cover that cost. If you can deliver your product and services quicker, you are more likely to win business in export markets. Sometimes that would take away the pressures on prices even. Now you are in the best part of benefits from lean implementation into your business. Lean is best at reducing your lead times and cycle times. That is the main aim of becoming lean. When you reduce your lead times, you don’t have to keep as much stock, your money frees up from that and your costs go down as well. Lean philosophy is all around reducing that and all the tools and techniques are designed to make a positive effect on that with a long list. Value stream mapping, takt time, just on time (I have changed the phrase knowingly from just in time, that is a matter for another article), heijunka, flow, pull systems, kanban and many more in that list. So, if you want to be more competitive in the local and export markets, lean is your answer.

Overall becoming lean is not complicated as much as you think. It only starts with value definition, some sense checking, using most of the ideas your employees already have in their mind to improve, and then bringing all that into a lean philosophy and direction will give you the competitive edge you need to compete all around the world.

Export for Lean

Every business would want to reduce their costs and improve their performance. Cost cutting exercises are being widely used in every industry since Taylor started using his stopwatch. Some initiatives have been very successful at times and some of them disappeared in short space of time. Lean is one of the many initiatives that has been around for decades and companies all around the world are continuing or aiming to start their journey.

I am sure some of the readers of this article will have no experience in Lean. Lean is not 5S, SMED, Kanban, A3, stock reduction, just in time nor kaizen. Those are just some of the many tools and techniques Lean would use for the same purpose. That purpose is understanding and delivering the value customers want in the shortest space of time by eliminating everything that stays in front of shortening the lead time (or cycle time). Cost reduction, stock reduction, just in time, better quality, better teamwork, better communications, and leadership is just some of the benefits of that purpose.

Without getting into how to get lean (which is a matter for another long article), let’s say you started your journey with lean and you became successful at it. Cost per product or service is down, shorter lead times are at present, customer satisfaction is high, and the list goes on. How can you sustain that?

Unfortunately, most businesses and most consultants see lean as a cost cutting and headcount reduction exercise and making a bad name for lean. Real lean creates more capacity with the same resources. If you start redundancies after you became lean, how can you continue to improve your business? How can you keep your employees happy and engaged? Eventually how can you keep your customers satisfied?

That is the main reason you shouldn’t see lean as an exercise only for production areas. Lean is an overall business strategy.

Why Export?

When you create capacity, you must fill that capacity with sales. Question I often face from business owners and directors is “We reduced our lead times and costs we increased our capacity, but we can’t fill it, so we need to let some employees from operations to go”. Some employees!!! Some employees that add real value to their product and services. Most of the time, my answer to them is “If you are not capable of selling more why don’t you think about changing your sales strategy? Clearly your sales strategy or your sales team is not good at selling better product and services with shorter lead times that established by implementing lean.”

When you create capacity, you must fill that capacity with sales. Question I often face from business owners and directors is “We reduced our lead times and costs we increased our capacity, but we can’t fill it, so we need to let some employees from operations to go”. Some employees!!! Some employees that add real value to their product and services. Most of the time, my answer to them is “If you are not capable of selling more why don’t you think about changing your sales strategy? Clearly your sales strategy or your sales team is not good at selling better product and services with shorter lead times that established by implementing lean.”

Same business owners and directors try to defend their position by saying “We reached the highest market share in the UK”, “Market conditions are not good for further growth.” In my view these are all excuses for them as they are enjoying the profits in the short term, and they don’t want to invest into activities for growth. Most of them do fail in the long term. Companies who are successful have been growing through more sales to existing markets and more export.

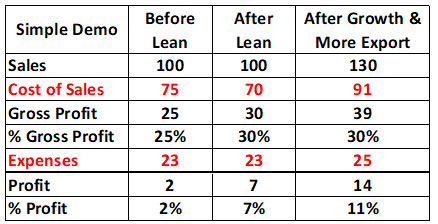

Just assuming you are not good with accounts, so I am keeping the example as simple as possible. I am sure most of you are familiar with the information in the table below. Starting from 100 units of sales, this demo is based on close to 7% direct cost reduction gain by lean (much more is possible) and 2 units more expense for growth and export. I try to keep it simple so please don’t start what if scenarios to prove your argument like those business owners and directors mentioned above.

We have been in and seen businesses that grows over 50%, with profits growing over 800% after a successful lean business strategy implementation. If you don’t grow after lean implementation, you enjoy benefits for 2-3 years. If you grow and export more, you enjoy more benefits every year for decades.

Do you think Toyota became Toyota by just reducing costs or head count? No. They became the best in their industry by making everything in shorter space of time and growing (selling more and more) with it. So, if you are not planning to grow your business, do not think about becoming lean. You will gain more profits in the short term, but you will fail in the long run.

If you are thinking about implementing lean or already started your journey, you must aim for more export in your strategy for sustainable and profitable growth. When you become lean you have everything you need in your products and services to be able to sell overseas. The world is your oyster.