Introduction to VSM

Why is “process” so important to Six Sigma and Lean? The straightforward explanation is that processes are the fundamental set of operations that give activities inside an organisation structure, efficiency, and control.

Therefore, in order to achieve the goal of continuous improvement, tools that enable stakeholders to assess and enhance processes are essential. One important methodology is value stream mapping. Anyone interested in investigating how Lean might be utilised to improve results and provide more value to the customer can use this effective methodology for describing, assessing, and optimising processes.

Value stream mapping is a lean manufacturing technique that involves information and material flow analysis, design, and management to bring a product to market. A system of standard symbols is used to illustrate different work streams and information flows in what is often referred to as “material and information-flow mapping”. To identify and eliminate products, processes that don’t contribute value, objects are mapped as either adding value or not adding value from the perspective of the customer.

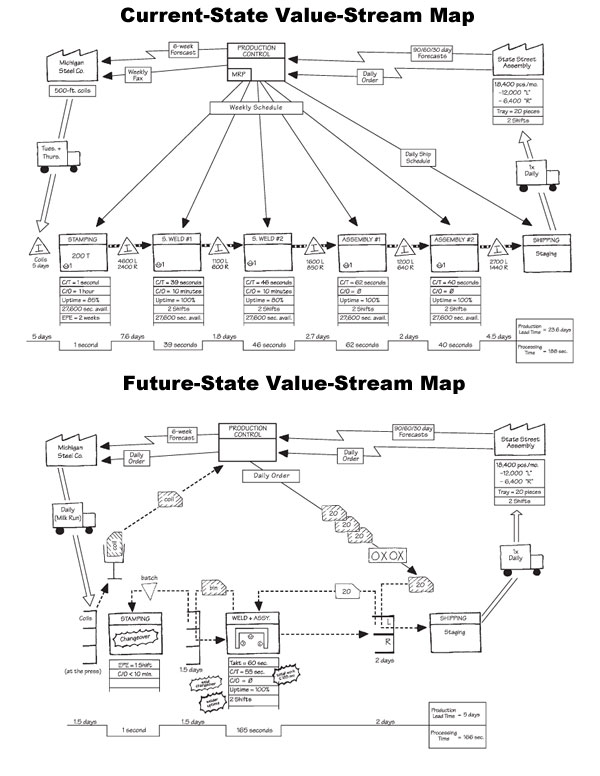

Any enterprise system’s selection and effective implementation depend heavily on value stream mapping, or VSM. Using a VSM, companies may produce a comprehensive work process flow diagram that shows every stage of the processes from order-to-cash, procure-to-pay, plan-to-produce, plan-to-inventory, forecast-to-monitor etc. After finishing mapping, a company will have a better understanding of how they currently operate and be able to identify opportunities for improvement by using Kaizen approaches. The VSM will guide the organisation towards a future state process map that illustrates how the organisation will function going forward, emphasising the advancements and efficiency gains, taking these areas of improvement into consideration.

The Motivation Behind Value Stream Mapping

There are various reasons why organisations would want to carry out a value stream mapping exercise. However, there are two main purposes for material and information flow mapping exercises:

1. Determine the current value chain that an organisation uses

Value stream mapping shows the systems, procedures, and resources needed to supply, manufacture a product or service from beginning to end. Certain important questions, like: What combination of systems, procedures, and resources does it take to satisfy a customer need?, can the waste be identified and improve the process for business value outcome

• At what point does the organisation’s value streams converge?

• Are there ways to simplify operations to better meet the demands of their customers?

• Are there opportunities to streamline and automate processes to satisfy customer needs

2.Optimize how value flows through an organization

Once the value streams have been identified, the secondary purpose is to provide organizations with the information needed to improve them. The idea that an organization should function as a unified, coordinated system, working toward a common goal, is one of the fundamental principles of Lean.

By creating a value stream map of the current state, organizations can make adjustments to it and arrive at a future state value stream map that meets their desired objectives. Value stream Mapping

• helps organisation visualize more than just the single-process level, enabling you to see the flow of work across all the processes.

• helps to see sources of waste and shows the linkage between material and information flow

• It provides a common language for talking about a process.

• It makes the decisions about flow valuable with the key time calculations and forms the basis for new improved and implementation of flow should operate.

Creating a value stream mapping

Step 1: Identify the Value Stream

Finding the value stream is a prerequisite for initiating a VSM map. In order to define the scope of the study, a particular product or service must be chosen, and its lifespan from conception to delivery must be mapped out. This step’s objective is to comprehend the beginning point, which is typically the moment the customer places an order or makes a request, and the ending point, which is when the customer receives the finished good or service. Determining the bounds of the value stream map guarantees that the analysis encompasses all pertinent operations.

Step 2: Gathering Data

Once the scope of the value stream is identified, the next step is to collect data on each step within this stream. This will involve collecting information on a range of aspects of the process such as:

• Cycle Times: The time taken to complete each step in the process.

• Takt Time: Takt time is a time within which a product needs to be finished according to customer demand.

• Lead Time: It is a total time taken by suppier to deliver the finished product customer.

• Value Added Time: It is a total time requires for all value added activities in a process.

• Changeover Times: The time required to switch from one task or product to another.

• Quantities Produced: The volume of output at each stage.

• Error Rates: The frequency of errors or defects at each stage.

• Other Relevant Metrics: Any other data that could impact the efficiency and effectiveness of the process, such as employee downtime, resource utilization rates, etc.

Step 3: Mapping the Current State

Once you have the data for each process, the step next phase is to create a visual representation of the current state of the process. This is the process map that provides a detailed diagram and includes all the elements of the value stream:

• Process Steps: Each step in the process is represented, often as rectangles.

• Material Flow: Arrows or similar symbols illustrate how materials move through the process.

• Information Flow: This includes how information is passed along the process, aiding in decision-making and process progression.

• Data Boxes: These are used to display the collected data at each step.

This current state map then serves as a baseline for which improvements can be planned and measured.

Step 4: Identify Areas for Improvement

Following the completion of the VSM, analysis should be done of the current state map to look for areas of waste and efficiency in the process. Common types of waste include: Transportation, Inventory, Motion, Waiting, Over Production, Over Processing, Defects and skills

Step 5: Designing the Future State

Based on the current state analysis, a future state more efficient and effective valu- added processes with improvement is developed eliminating the wastes. The future state justifies and provides a practical achievable vision for process improvement to increase the organisation revenue and decrease the cost by eliminating waste.

Step 5: Implementing Changes in ERP and Continuous Improvement

Implementing improved processes in the organisation’s ERP software requires a collaborative effort across different disciplines with organizational structure change, roles and responsibilities. VSM is a continuous improvement activity, and the entire cycle reiterates to find further improvements as the business priorities changes

The current-state map enables organisation to visualize VSM a shared understanding of how each step in the process delivers value to the customer, including the material and information, and identify areas of improvement. The future-state map similarly creates a shared understanding of how the process will work once the team makes improvements, serving as a roadmap of improvements.

Benefits of Value Stream Mapping

• Value stream mapping is essential to the long-term viability of businesses. This is the reason why Cutting and getting rid of waste non-valueadded process or products can help streamline business.

• Inefficient handoffs can be identified quickly and easily to proactively enhance cooperation, culture, behaviour and communication encouraging teamwork and disregard silos

Challenges of Value stream mapping

• As value stream mapping can be a highly complicated and cross-functional exercise, including seasoned individuals from the business and product sides in its execution to prove the benefits

• It is important to weigh the possible value and savings against the LOE (level of effort) required to do value stream mapping. Monitor the return on investment (ROI) from the start.

• Waste identification can be laborious time-consuming procedure causing fear and uncertainty as side effects of value stream mapping.

• There definitely will be savings or cost reduction making small improvements and removing unwanted processes.

Conclusion

There are numerous options for input from the shop floor, manufacturing line, and operational level to identify and solve problems that can be configured in a range of modules in an ERP system. An overview of all the components of the processes in place can be obtained by mapping the value streams in each department, including production, purchasing, marketing, technical, accounting, human resources, and customer support. Using the current, ideal, and future as lenses, it is possible to bring value added processes into sharp focus. Lean concepts applied to a range of software solutions will give organisation a competitive advantage by simplifying the implementation of optimised processes throughout the entire organisation.