Lean World

Over the last 30 years, there has been thousands of companies tried to implement Lean processes into their businesses. There have been many studies to find out how those companies were doing after its implementation phase and the results are very discouraging. Out of the many companies starting their Lean journey only 2% of them have seen good results and achieved their objectives. There are many facets to these failures during the Lean implementation stage and it is not easy to cover all of them in one article. Nevertheless, let’s have a look at some main issues regarding these failures.

Paradigms the World Created Around Lean

Even before we look at any business and talk about any failures, there are fundamental challenges around Lean created by the early days of Lean definitions. Some of these challenges are created by leading consulting companies all around the world.

Lean Manufacturing

Unfortunately, the philosophy came out as Lean Manufacturing all around the world. This created the understanding in businesses that Lean is all about manufacturing. It should have been called Lean Enterprise from the start. As a result of this paradigm most businesses ignored Lean if they are not a manufacturing business. Also, the manufacturing businesses gave the responsibility only to production departments. Lean Manufacturing name ended up alienating either other businesses or other departments within the organisations.

Making the same output with using half of the resources

This sentence has been used by many consulting companies as a selling point for implementing Lean into other businesses. Lean actually results in using the same amount of resources for almost doubling the output. Companies hooked up by those consultancy companies -with this wrong explanation- expected reductions on cost and headcount. Cost reduction is an inevitable outcome of Lean implementation, but it is not achieved by headcount reduction. Lean potentially increases the headcount by helping companies to grow more with creating customer satisfaction on all three measures quality, cost, and delivery.

Lean Means Zero Stocks

JIT (Just In Time) was translated into zero stock by many implementors. Lean is aiming for minimum / optimum stocks for best customer satisfaction. Lean is for reducing the throughput time by following Lean Principles which reduces waste, unevenness, and overburden within the organisation.

Lean is 5S, SMED, TPS, JIT, A3 etc.

They are just the tools and techniques available in the Lean Toolbox. They are very powerful for making improvements in any process but when a business applies tools without the Lean principles all those tools become additional cost to the business and doesn’t improve the bottom line.

5 LEAN PRINCIPLES

After mentioning these paradigms, we need to remember Lean Principles.

- Specify the VALUE in the eyes of the customer

- Define the VALUE STREAM and eliminate waste and variation

- Make the vale FLOW by eliminating waste and variation

- Implement PULL systems for customers (internal or external)

- Seek PERFECTION by following the principles again and again.

We have been in so many different businesses over the last 20 years. Businesses in different industries, in different markets, in different stages of their implementations. We have seen different examples of failures and successes over the years. Common themes in those companies are:

| Failing Companies | Successful Companies |

| · Start with 5S in a pilot area.

· Focus on 7 wastes (Muda) · Focus on lean tools and techniques. · Improving parts of the value stream. · Focus on cost per piece. · Improving efficiencies. · Involving only the people in production. · Part of a manufacturing strategy. · Managed by middle managers in manufacturing. · Copying implementations from automotive. · Aiming for Just in Time and zero stocks. · Trying to run so many Kaizen projects at the same time for long time. |

· Start with identifying Value

· Focus on Value Stream and Flow · Focus on Lean principles and Flow. · Improving the whole Value Stream. · Focus on P&L effect. · Improving effectiveness. · Involving anybody and everybody. · Overall business strategy. · Managed by directors, owners, or top management. · Bespoke implementation for each company. · Just on Time and optimum stocks. · Focusing on Kaikaku* projects and finishing them in short space of time. |

*Kaikaku is implementing a radical change in 5 days rather than improving in small steps (Kaizen), it is called Kaizen Blitz in some places.

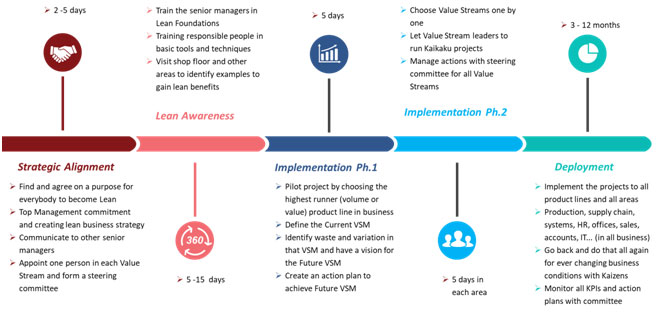

Below you can find a typical road map for implementing Lean into any business, any size and in any industry.

How to Avoid Lean Implementation Failures

In a nutshell:

- Choose a consultant or facilitator who understands all departments and business as a whole.

- Identify and communicate a reason for everybody to become Lean.

- Use Lean as a business strategy, Lean is not just for manufacturing department.

- Focus on growth, not the headcount.

- Don’t start with tools and techniques, start with value and value stream.

- Don’t create improvement projects in isolation, think about the whole picture.

- Run quick Kaikaku* projects and finalise as soon as possible to show results and benefits to everybody.

- Involve all departments including suppliers and customers.

- Every business is different, one fits all type of implementation doesn’t work in most businesses. Accept that and choose only tools and techniques that are right fit for your business during implementation.

- Aim to create customer satisfaction instead of management satisfaction.

- Manage the implementation process with steering committee that has top management in it.

- Don’t do anything that doesn’t increase the turnover or doesn’t decrease operating expenses and stock.

As explained at the beginning, there are many facets to a failing implementation and it is not possible to cover all of them. If a business can follow the narrative explained above, they have a very good chance of being in the 2% of those businesses that are successful in Lean implementations and excelling within their industry against their competition.