There is growing recognition that companies no longer compete as individual entities, but rather as part of a broader network (Chen-ha et al, 2014; Christopher, 2016). The strength of these networks is largely determined by the quality of relationships that connect companies and the business processes that sustain them. While the resource-based view of the firm attributes competitive advantage to the ownership, control of resources, and the unique capabilities of a single firm, the relational view extends this theory, considering interfirm relationships as an important unit of analysis for understanding differential performance in business and according to this relational view, rents are created when companies combine, exchange or invest in unique assets, sharing complementary knowledge, routines, resources and capabilities, as well as effective governance mechanisms. Implementing cross-functional and cross-company business processes provides managers with responsibilities that facilitate the exchange of knowledge and skills across internal and external organizational boundaries and this is very special in logistics, where the core business is radically different from the one a traditional company uses to handle.

We’ve all heard that Brazil is a giant. And, like the giants we know from fairy tales, it has its own unpredictable nature that can make things difficult. This analogy can be used in our logistics and supply world. When in such a situation, what exactly happens and how do we manage the giant’s bad mood?

First of all, we should take a closer look at this giant. Brazil is 8.514.000 km2 in area, and is home to 204 million people. (2010 data). In 2014, Brazil’s estimated nGDP was as high as US$ 3,072t. Just to compare, Canada has 9.984.000 km2 and is home to 34 million people, with an estimated GDP of US$ 1,793t. Brazil is a giant that offers a Human Development Index (HDI) of 0.755 and his bad mood becomes apparent when we notice Canada has a an HDI rating of 0,913. To keep things working, Brazil logistics issues result in costs that that represents GDP’s 11.7%, a tad higher than USA’s 8% 2013-based costs.

Government policies are an important part of this huge logistic bill. One example of such this issue is the tax dispute between states, which creates situations that result in pharmaceutical goods being manufactured in Northeast states but having them consumed in the more populated Southeast region, creating a huge logistics problem. In other words, we send products 2.000 km for no other reason than politics, mainly using highways that are not in the best shape. Air transport in Brazil does not have the capacity that permits full service on drugs distribution, forcing us to use planes for major hub transfers but living with a potential last-mile syndrome. This is a real nightmare for cold-chain transport planners and an ever-present difficulty for distribution companies that must guarantee 2-8oC within 48 hours, most of the time with no insulated trucks. The use of subcontracted drivers just adds another level of unpredictability to this equation.

Enormous contrast in Brazilian highways – from modern and safe ones to others impacted by rainy season on the North region.

Enormous contrast in Brazilian highways – from modern and safe ones to others impacted by rainy season on the North region.

On such a complex scenario, our daily challenge is to avoid damages to perishables loads, mitigating situations that could ruin goods – thus impacting service level – and to continuously search for solutions to risky situations. In the same sense, some big companies must be humble enough to admit that logistics is not their core business and must rely on partners that do know what are the best alternatives or suggested actions on each distribution problem that appears. To find the correct, trusted and reliable partner is the “More-than-a-Million” worth situation. The company in which we deposit our goods and our brand must surely deal with topics like proper training of their personnel and a correct use of devices such as thermal blankets/containers, in the same way they guarantee adequate contingency plans even for well-known routes.

Looking at the broader view, over the last twenty-or-so years many companies have increased the usage of 3PL companies along their supply chain process as most have identified the correct core-business and migrated to this solution. As pharmaceutical companies we are not different, but with one added roadblock for proper service providing, which is the need for robust Good Distribution Practices & Good Manufacturing Practices systems that guarantee that all offered services are in compliance with the strict requirements we face – even some pharma-based companies working with OTCs and Cosmetics must follow good manufacturing requirements. In spite of having quality systems in place that have proven themselves as state-of-the-art service providers and verified through frequent audits, there is a natural tendency to control these activities from a vendee perspective and hence increase these controls over activities from time to time. When we have systems and processes with proven reliability and confidence, it’s time to move one step further towards other activities that once were kept in our hands. This kind of virtuous dynamic cycle system, although being a recognized value-added one, needs some intelligence to be supported as we frequently get ourselves in crossroads like:

Partnership X Relationship: How to take that step forward that moves us from a partnership to some kind of stable reliable relationship where both parts wants to achieve success?

Reliability X Commitment: Is our counterpart reliable or committed? What’s the difference between these two concepts and how do we enhance one over the other?

Productivity X Costs: Do we need to lower costs through lower prices? Or are we mismatching words, when what we do strive for is productivity and excellence?

These are a few of the main questions we have when dealing with external partnerships, rated as important as costs increase, contract negotiations, penalties, price adjusts and so on. But there’s always a light at the end of this tunnel. After defining that we do want and need in a long-lasting relationship, only its adequate management will turn this model into reality. An effective Relationship Management goes beyond a governance model overcoming the sense of “the processes of interaction and decision-making among the actors involved in a collective problem that lead to the creation, reinforcement, or reproduction of social norms and institutions.”[1]

[1] https://en.wikipedia.org/wiki/Governance

This relationship management naturally includes metrics and actions that are monitored as any in governance model, but also aggregates values and behaviors that although being somewhat intangible are the fundamental stone on the way we want to do business. When we rely on values that are common to both companies – or that are built up together – the basic idea is to increase CMO/3PL reliable productivity. This is something that both parties want, since it permits continuous growing and is what will add value to the company, either to the vendor or vendee. The Virtuous Cycle that results from this relationship has just one target: an everlasting consistent service level. We want our counterpart to be successful and the mental image I have is that of a paddle ball game, beach tennis like, where the objective is to play in such a way that our “opponent” hits and continues giving the ball back to me.

Different from tennis, where we want to beat the other player, collaborative relationship is like a paddle ball game, where the objective is a continuous playing mode.

Different from tennis, where we want to beat the other player, collaborative relationship is like a paddle ball game, where the objective is a continuous playing mode.

I’ve mentioned earlier the need and benefits of a correct relationship management, but what does it really stands for? From my perspective, it’s basically the approach and the way we interact with others. A basic but more-than-vital relationship management happens at home with your wife and children – and as father of three boys, sometimes I face scenarios much more challenging and complex than some situations with my Director’s Board. Imagine a hypothetical situation when your wife wants to visit her parents on a Sunday afternoon, in the same time you want to see that football match on your favorite couch. Not so uncommon, right? How do you manage this situation? Would you say “I won’t go” or even “you go alone” (which is much worse) and create a tense situation or would you rather state “Ok, I want to go too but could it be just after the game?” The point is to understand the others perspective/constraints and negotiate it in a win-win agreement, most of the time with no direct monetary values involved. Someday you might have to watch the game with your not-so-dear father-in-law, and deal with it the same way you deal with complex situations at work. If it happens frequently, deeper discussions are needed but always with respect and focused on the main topic. I believe that economics, administration and negotiation background are needed for someone in an external relationship model, but Conflict Management trainings are the ones that do make the difference in this role.

Inn a 3PL or CMO – Contract Manufacturing Organization – you will always seek to optimize a committed business relationship over an engagement-type one. To differentiate both, I use the “Eggs and Bacon Postulate” comparison, simply explained as: For your brunch, when you want bacon and eggs, the chicken is engaged in the process, while the pork is committed. Not that your professional partners have to be sacrificed – lucky them! – but the level of involvement we have is remarkably different. We want a 3PL that suffers and succeeds with us.

Engagement vs. Commitment

In order to get a strong and respectable connection one simple point is needed: you must like the other part, and to like it you must know your counterpart. It’s surprising, from a professional perspective, how you must go deeper into their process, be familiar with their hardware and equipment, and feel relaxed when walking through their warehouses to become more and more like feeling at home. After better knowing your partner’s company and their potential, you’ll be feeling comfortable enough to start teaching them what you want.

I remember a situation when I was hired to work in a Danish pharmaceutical company. They had moved between different 3PLs in a short time. Service level was nothing but terrible and we were losing market share due to poor On Time in Full – OTIF – rates. Thus, the Director’s Board was considering moving back to one previous partner. As the new Logistics Manager, I was then asked about what to do and my very first comments were “Did anyone tell this new partner what do we expect from them? Do they know our process in detail? Do we know their bottlenecks? If we move back to previous suppliers, we’ll lose our negotiation advantage”. As a matter of fact, no one was very sure which path we should take. It was then decided to keep the current supplier and get deeply involved in their operation. So I did, and OTIF numbers rose from 41% to 94% in just about three months.

This is just to reinforce that when you like and know your partner, you can easily teach the way you want things done and can pick the low hanging fruits in a short period.

Each vendor, partner, CMO or 3PL has its unique and special features that must be known. Our role while on external managerial functions is to help them to develop into precious stones. Part of their commitment with us starts when they realize we do not want just positive audit results, but a joint-growing process. To help in this evolution process sometimes we must advocate for these partners by finding shortcuts or alternative answers in our own companies since only we know how complex big contractors like ours are. A continuous discussion and a true help in developing our partners, managing them with transparency and honesty while keeping our contractor’s hat will be perceived with true respect for business continuity. And we must remember that in certain moments we will drift from B2B to people-to-people relationships, and for these times a mutual respect is the driver for all further actions.

After building up a true relationship, with respect for the people and knowledge of others capabilities, we can move forward to guarantee that sensible topics, like cold-chain distribution processes, are properly managed by our counterpart.

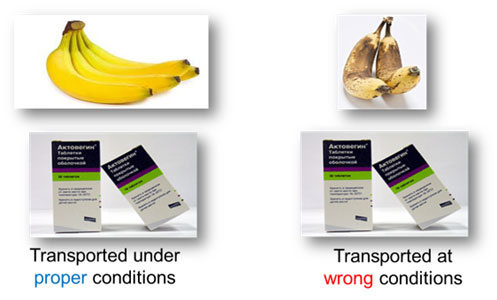

Some products are noticeable damaged under improper transport conditions, others don’t . Only an open honest dialogue will guarantee that our customers receives adequate product.

Some products are noticeable damaged under improper transport conditions, others don’t . Only an open honest dialogue will guarantee that our customers receives adequate product

As a matter of fact, to effectively manage your temperature-controlled logistics through an improved external relationship management, some steps might be considered. First, one must be sure to have a strong Customer Relationship Management – CRM – equivalent implemented for formal governance and in this sense a Vendor Managed Inventory – VMI – process would even improve this control. My first VMI, established in late 1996, was managed by my chemicals’ transport company. But please also take into account that a solid Sales & Operations Plan Process permits a feasible delivery route through the use of planned dispatches, with transit times within 48 hours for most customers. And one question here: have you ever wondered about bringing your 3PL to your companies’ S&OP? If not, why? Have you ever thought how committed they’d be upon joining you into this process? The open-hearted talk obtained through this relationship model guarantees full support to quality, and avoids unnecessary risks taken by the 3PL.

I do believe that the main steps to success in this journey can be easily achieved through use of simple steps such as:

• Maintain an inter-dependent team with shared goals and honest cooperation between both companies. A commitment and compromised group is born when common targets are set.

• Obsession for Performance. Both sides must be set for a never-ending chase for Quality, Service, Technology, Cost, No Waste…

• Bear in mind that you might be building up a robust long term P2P relationship, rather than only contract-managed discussions. Today I have former contractors in my Facebook page! Companies may even fade away, but the relations you build will last much longer.

• Celebrate. Take some time to celebrate your achievements. Invite your 3PL partner for a lunch – and not the contrary, as we use to see.

Relationship management is an exercise of patience and tolerance – internal and external to your company, but when properly done I guarantee you will build up MASSIVELY STRONG bonds that can positively reflect in your daily challenges. Hope you do get such gigantic connections as strong as the giant we met earlier in this article.