How to get rid of huge amounts of paperwork on industrial construction sites? For site managers this is one of the most important questions when it comes to material tracking and deviation management.

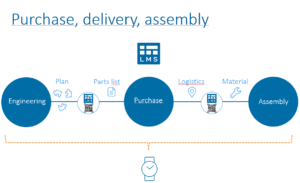

On industrial construction sites, usually a considerable amount of time is spent on tracking and searching materials. Many companies still work in a non- or partly-digitalized process environment. Ideally the whole process from engineering to purchase, logistics and site logistics, and finally to assembly can be tracked with software, which uses barcodes or RFID tags to identify an item. Most companies do not integrate the software in the whole procedure which can be critical.

The process for material tracking is basically the same in every company, but the data which comes from engineering departments or other vendors differs to a certain extent. It is imperative to incorporate the right tools into a process which are interlinked with other systems to get the best results.

Paperless sites through suitable processes

The goal: Paperless documentation, flashing 3D models with live status updates of the construction site and increased efficiency. But, this goal is not reached with big data. This goal is reached by setting up a proper process which fits for the respective company.

The biggest challenge in digitalization projects is to set up clean processes – the foundation for every change. Different departmental emperors, a wide variety of ways of working, various in-house-custom-made solutions and the “we-always-did-it-like-this” mentality are usually the real obstacles to digitize construction projects.

The biggest challenge in digitalization projects is to set up clean processes – the foundation for every change. Different departmental emperors, a wide variety of ways of working, various in-house-custom-made solutions and the “we-always-did-it-like-this” mentality are usually the real obstacles to digitize construction projects.

Software can support processes and make good companies even better, but an app alone does not solve any problem.

The strikingly flashing 3D model of a building with live status updates is praiseworthy, but difficult to implement without clean processes – starting with engineering, bills of materials, purchasing and shipping through to installation on the construction site.

The first step is the most important!

First, digitalization must be transformed from a buzzword to clear benefits for each involved employee which ultimately benefits the company. Even if it is difficult – forget the all-in-one solution suitable for every purpose. Through the definition of small steps, a rapid prototype (“proof of concept”) and quick first successes, one can gain momentum and incrementally enhance and build trust in a new solution.

The essential assets of industrial plant manufacturers are know-how and employees. Ultimately, they also decide on success or failure of new software projects. Clear advantages for the end-user, substantial work simplification and a modern and simple user interface are mandatory.

Collaborating with innovative and specialized partners is a great way to take a foothold in the virtual world of tomorrow and gain a competitive advantage. This may not necessarily result in immediate financial benefits, but a transformation to digital processes is absolutely necessary for plant manufacturers in the most diverse areas. Standing still simply lead to a long-term competitive disadvantage.

That´s why everyone should keep in mind: keep up with the times and time won’t pass you by!

About the author

Thomas Roithmeier, CEO & Co-Founder INSITE IT GmbH

INSITE IT is specialized in material management, deviation management and site logistics on industrial construction projects. The advantage is to track all materials needed on a construction site to help avoiding standing times. The Austrian based company provides Apps (Android, iOS) for mobile phones and a Windows tablet app to track all material onsite