Over the years, many unique elements have tried to define human beings, and yet none have done a better job than our tendency to improve at a consistent pace. This unfaltering commitment towards becoming a better version of ourselves, no matter the situation, has really enabled the world to clock some huge milestones, with technology emerging as quite a major member of the group. The reason why we hold technology in such a high regard is, by and large, predicated upon its skill-set, which guided us towards a reality that nobody could have ever imagined otherwise. Nevertheless, if we look beyond the surface for one hot second, it will become clear how the whole runner was also very much inspired from the way we applied those skills across a real world environment. The latter component, in fact, did a lot to give the creation a spectrum-wide presence, and as a result, initiated a full-blown tech revolution. Of course, the next thing this revolution did was to scale up the human experience through some outright unique avenues, but even after achieving a feat so notable, technology will somehow continue to bring forth the right goods. The same has turned more and more evident in recent times, and assuming one new discovery ends up with the desired impact, it will only put that trend on a higher pedestal moving forward.

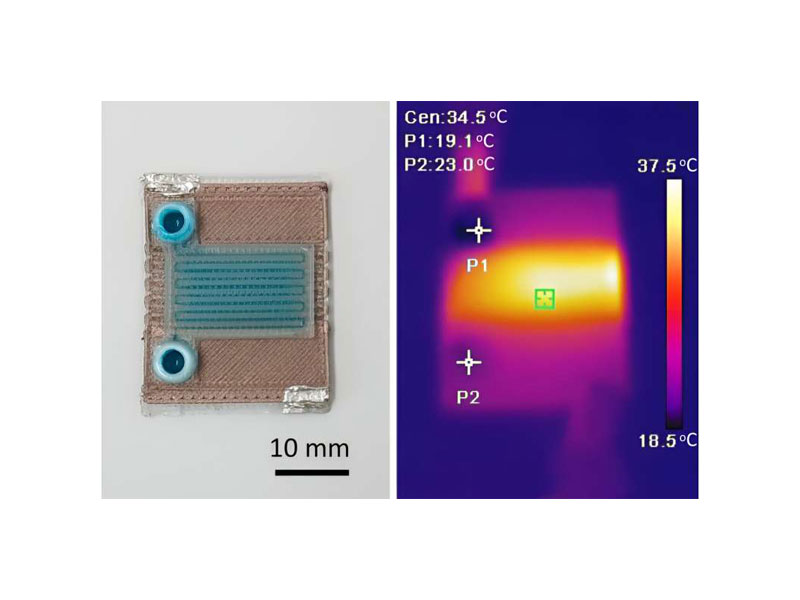

The researching team at Massachusetts Institute of Technology has successfully developed a technique where we can use 3D printing to produce self-heating microfluidic devices. This technique, on its part, will help us rapidly create cheap, but accurate, tools to detect a whole assortment of diseases. You see, microfluidics basically translate to these miniaturized machines that manipulate fluids and facilitate chemical reactions to generate the patient’s diagnosis from a blood or other fluid sample. Now, while the technology is already being used in the form of, for example, at-home test kits for COVID-19, it continues to face one big challenge. The stated challenge digs into how various microfluidic applications require chemical reactions that must be performed at specific temperatures. Another limitation in play talks to the fact that such devices are typically manufactured using heating elements made from gold or platinum, forming a process which involves complicated and expensive fabrication. Now, given the complexity and high value of the required ingredients, it becomes instantly difficult to scale up the method. So, how did MIT researchers solve this conundrum? According to certain reports, they applied multimaterial 3D printing to create self-heating microfluidic devices with built-in heating elements, and they did so in a single and inexpensive manufacturing process. In practice, the team used two materials, a biodegradable polymer known as polylactic acid (PLA) that is commonly used in 3D printing, and a modified version of PLA. The modified PLA had mixed copper nanoparticles into the polymer, which converted the insulating material into an electrical conductor. Anyway, the researchers used the copper-doped PLA to 3D print a heating resistor before finally conceiving the microfluidic device. The microfluidic device came bearing specialized channels through which fluid can flow directly on top in one printing step. Once the framework was ready, they fed electrical current into the resistor, a move which saw the energy eventually dissipating as heat. The resulting heat would warm the liquid flowing through the microfluidic device’s channels to get whatever reaction that might be desired. Interestingly enough, as the components used are made from a common base material; they have similar printing temperatures, a feature which goes a long way in reinforcing their overall compatibility.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” said Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL), and senior author of a paper describing the fabrication technique.

Apart from the resistor and the basic microfluidic mechanism, the MIT researchers banked upon 3D printing to install a thin and continuous layer of PLA. This particular step in itself was hugely critical because the said layer has to be thin enough so heat can transfer from the resistor to the microfluidic, but not so thin that fluid ends up leaking into the resistor. Moving on from that, the PLA material used for the job also makes a point to be translucent throughout the proceedings. This detail turns useful when you acknowledge that many processes rely on visualization or the use of light to infer what is happening during chemical reactions.

To achieve their final outcome, the researchers used multimaterial extrusion 3D printing, a method where several materials can be squirted through the printer’s many nozzles to build a device layer by layer. Not just that, the method in question is also monolithic, meaning the entire device can be produced on the 3D printer in just one step, and it can be done without the need for any post-assembly.

“Being able to directly print microfluidic chips with fluidic channels and electrical features at the same time opens up very exiting applications when processing biological samples, such as to amplify biomarkers or to actuate and mix liquids. Also, due to the fact that PLA degrades over time, one can even think of implantable applications where the chips dissolve and resorb over time,” said Niclas Roxhed, an associate professor at Sweden’s KTH Royal Institute of Technology, who was not involved with this study.

As a way of testing their latest brainchild, the researchers recreated this one-step manufacturing process to generate a prototype that could heat fluid by 4°C while it is flowing between the input and the output. The incentive to do so was finding whether they can put-together a technique which is customizable enough to make devices that will then go onto heat fluids in certain patterns or along specific gradients.

“You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” said Velásquez-García.

Despite the huge potential, there remains a big limitation with how PLA can only be heated to about 50°C before it starts to degrade, whereas chemical reactions, such as those used for polymerase chain reaction (PCR) tests, require temperatures of 90° or higher. Beyond that, before enabling anyone to precisely control the temperature, the device would need a third material that enables temperature sensing. For future, the researching team’s plan is to address these questions, but that’s not all. They will also try and print a set of magnets directly into the microfluidic device. This will produce chemical reactions that require particles to be sorted or aligned. Furthermore, in context of the earlier downside, there is an idea to bring in different materials that can reach higher temperatures. Complimenting the same is an effort geared towards studying PLA to better understand why it becomes conductive when certain impurities are added to the polymer.